P.Shale take this opportunity to introduce our Company as a supplier of complete range of industrial gaskets conforming to all international standards,

• Valves & Fittings

• Fasteners and stud bolts

• Sheet plates

• Pipes

• Filters

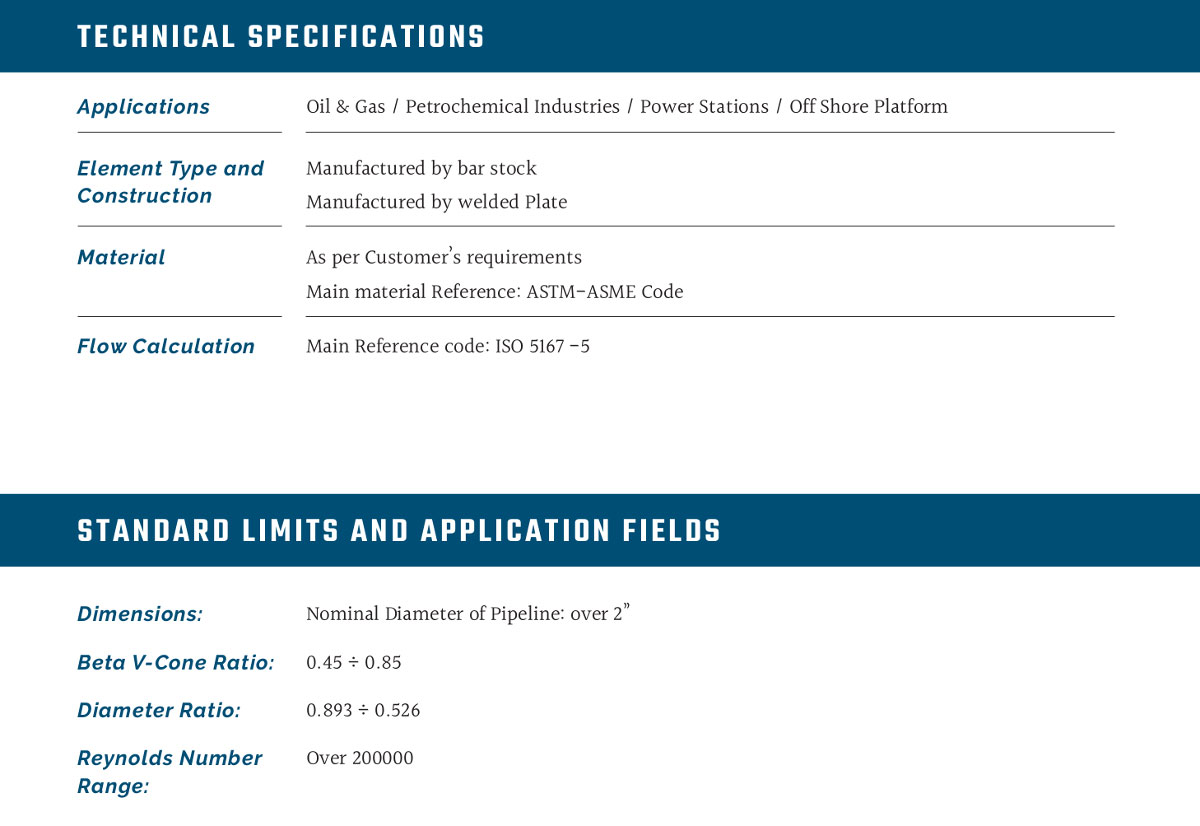

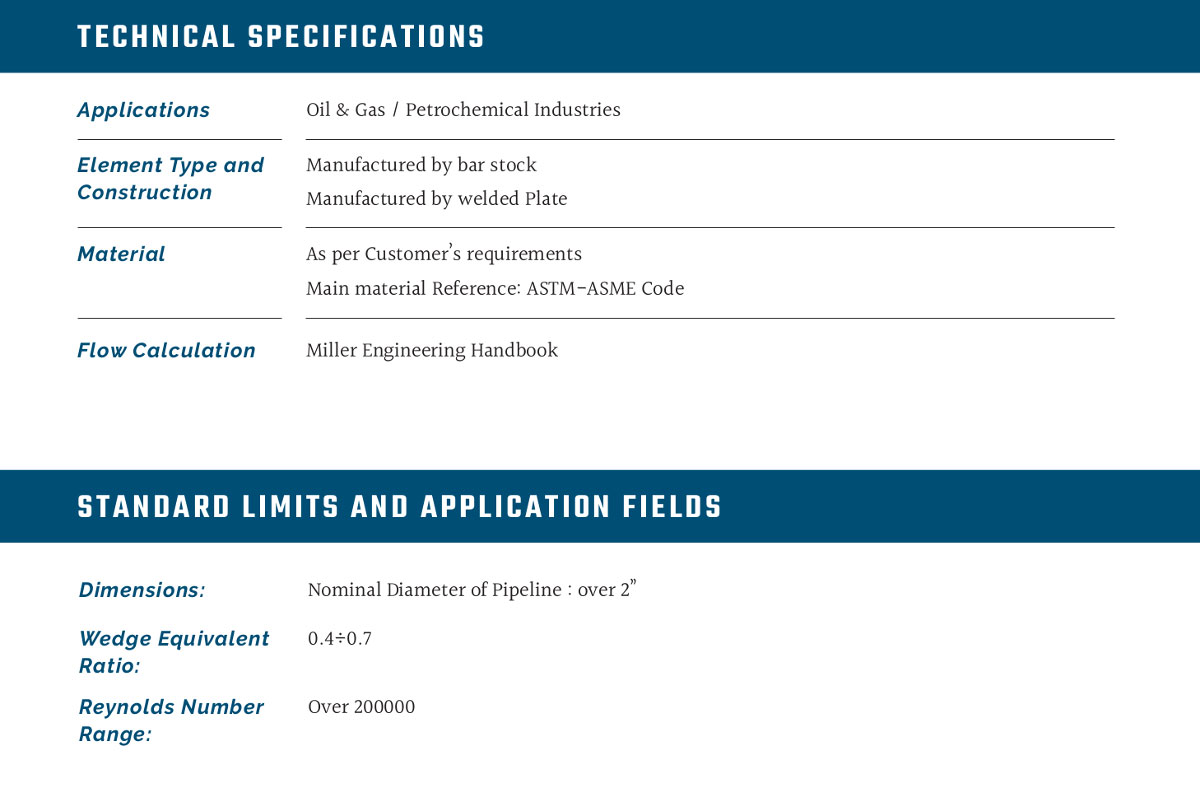

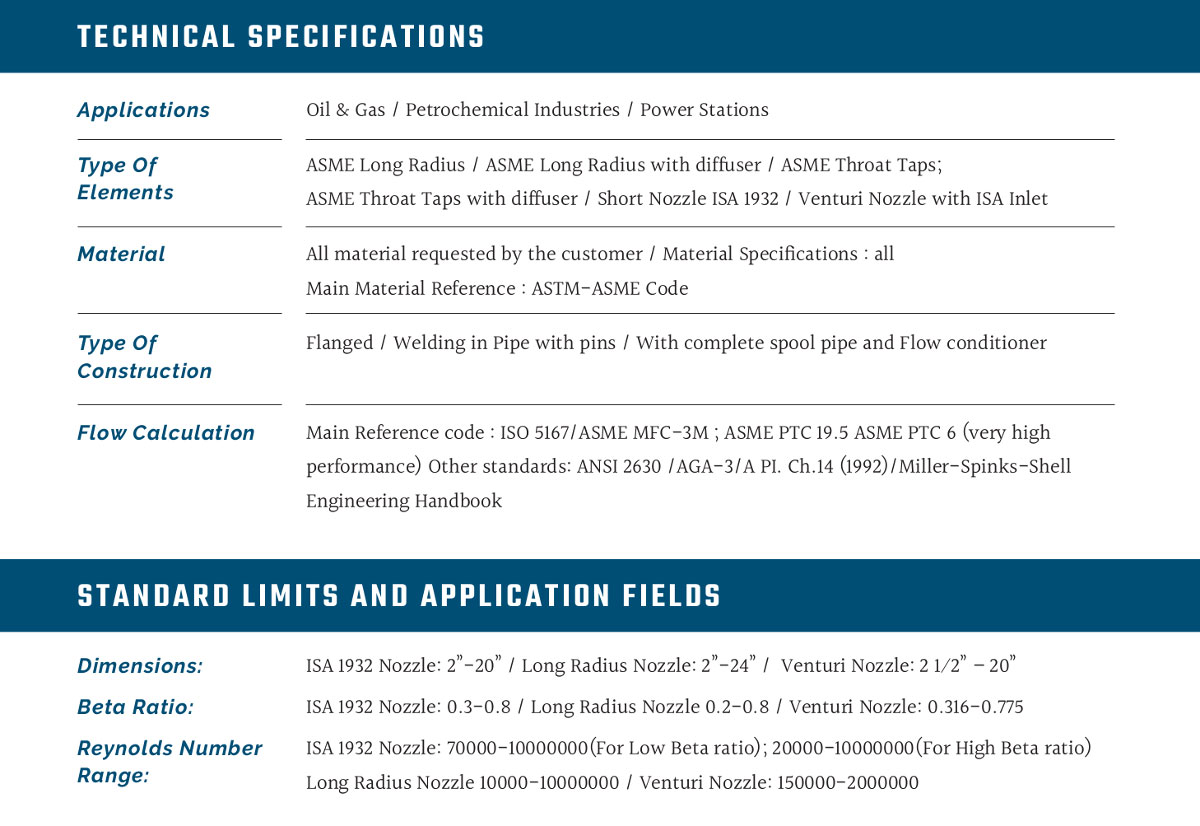

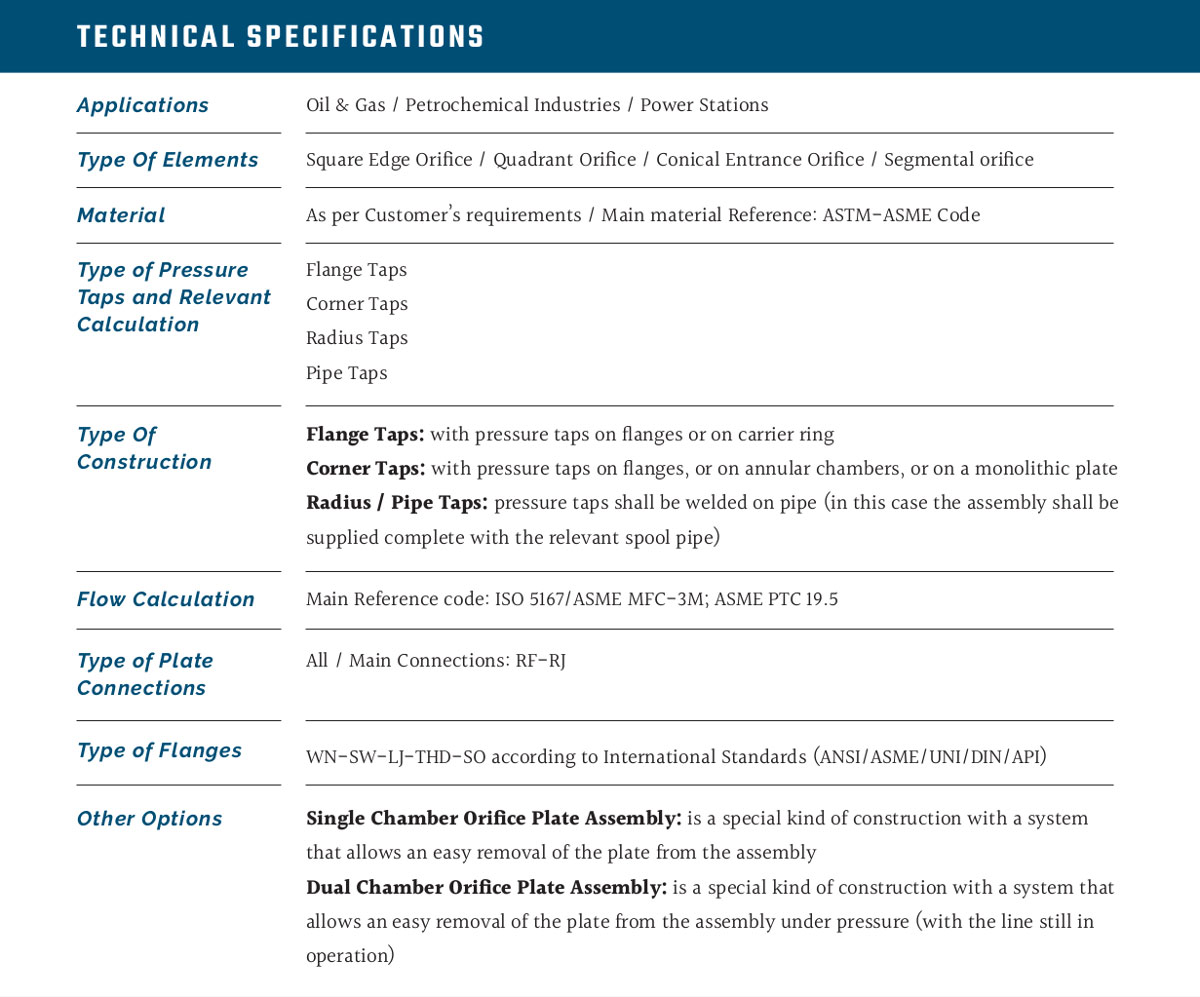

• Flow & temperature meters

In addition, we excel at speed, flexibility, and convenience when getting critical industrial supplies to our customers